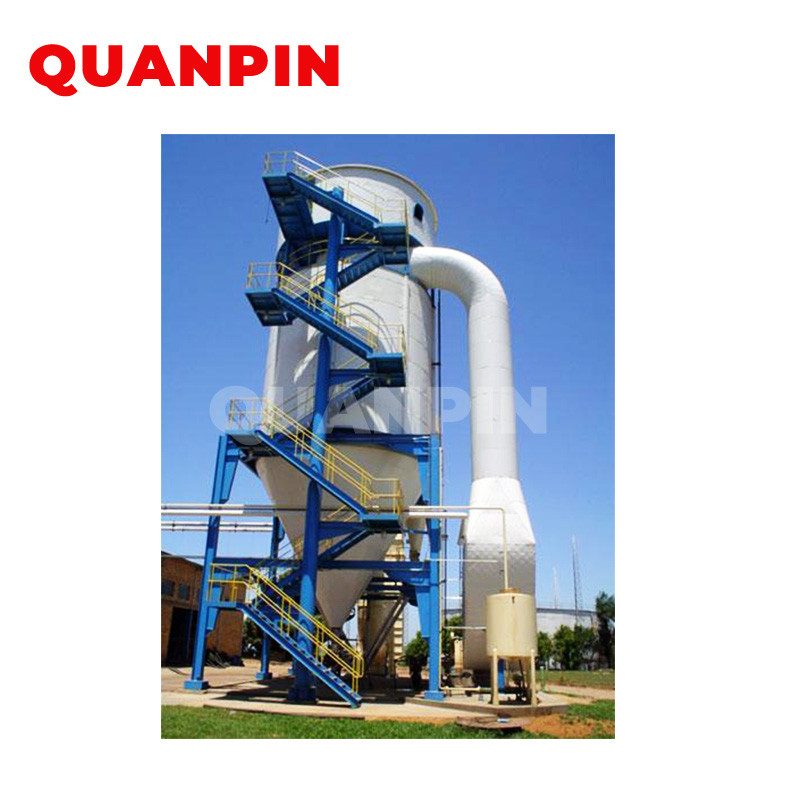

I-LPG Series High-Speed Centrifugal Spray Dryer enexabiso elikhulu

Iinkcazo

Ukomisa ngokutshiza yeyona teknoloji isetyenziswa kakhulu kwiteknoloji yokwenza ulwelo nakwishishini lokomisa. Iteknoloji yokomisa ifanelekile kakhulu ukuvelisa umgubo oqinileyo okanye iimveliso zamasuntswana ngezinto ezingamasuntswana, ezinje: isisombululo, i-emulsion, i-suspension kunye ne-pumpable paste, ngenxa yesi sizathu, xa ubungakanani bamasuntswana kunye nokusasazwa kweemveliso zokugqibela, umxholo wamanzi aseleyo, uxinano lobunzima kunye nesimo samasuntswana kufuneka sihlangabezane nomgangatho ochanekileyo, ukomisa ngokutshiza yenye yezona teknoloji zifunwayo.

Ividiyo

Umgaqo Wokusebenza

I-Spray Dryer yokuvula umjikelo kunye nokuhamba, i-centrifugal atomization. Emva kokomisa umoya ophakathi kwangethuba, izihluzi zomoya ezisebenzayo eziphakathi kunye nezihluziweyo ngokwemiyalelo yokusebenza ngokutsalwa, emva koko zifudunyezwe yi-heater blower, isihluzi esisebenzayo esiphezulu singene kwi-hot air dispenser, sitshize i-spray dryer kwi-main tower. Emva kokuba izinto ezingamanzi zifakwe ngokwemiyalelo yokusebenza, i-peristaltic pump ijikeleziswa ngesantya esiphezulu, amandla e-centrifugal asasazwa abe ngamaconsi amancinci. Kwi-Spray dryer, i-main tower enomoya oshushu, amaconsi amancinci adibene ngokupheleleyo, omiswe ngokutshintshana kobushushu kunye nemveliso ecaleni kwendlela ethile, emva koko ngenkanyamba ukuze kuphunyezwe ukwahlukana, izinto eziqinileyo ziyaqokelelwa, zihluzwe, emva koko zifakwe i-gaseous medium, emva koko zikhutshwe. Spray yonke inkqubo kulula ukuyicoca, akukho ziphelo zifileyo, ngokuhambelana neemfuno ze-GMP.

Amanqaku:

1. Ukudibana namathontsi omoya oshushu: ubungakanani obaneleyo bomoya oshushu ongena kwigumbi lokomisa isitshizi kufuneka buthathwe njengecala kunye ne-engile yokuhamba kwegesi eshushu, kwaye nokuba kukuhamba, ukuhamba okuchaseneyo okanye ukuhamba okuxutyiweyo, ukuqinisekisa ukuba ukudibana ngokupheleleyo nethontsi kunokwanela ukutshintsha ubushushu.

2. Isifutho: Inkqubo ye-atomizer yesifutho kufuneka iqinisekise ukusasazwa kobungakanani bethontsi ngokulinganayo, nto leyo ibalulekileyo. Kuba ukuze kuqinisekiswe ukuba izinga lokudlula lomgangatho wemveliso liyanda.

3. Ne-engile ye-engile yekhowuni yoyilo lombhobho: Sifumana idatha ethile eqinisekisiweyo kwimveliso yeeyunithi eziphantse zibe liwaka zeqela le-Spray Dryer, kwaye singabelana ngayo.

Uphawu:

1. Isantya sokomisa isitshizi, xa ulwelo lwezinto lufakwe kwi-atomized, indawo yomphezulu inyuke kakhulu, umoya oshushu udibana nenkqubo, umzuzu unokuba yi-95% -98% yokufuma komphunga, ixesha lokomisa lithatha imizuzwana embalwa, ingakumbi kwizinto ezinobushushu ezomileyo.

2. Le mveliso ifana kakuhle, inyibilika kwaye iyanyibilika, icocekile kwaye isemgangathweni olungileyo.

3. Inkqubo yokuvelisa i-Spray Dryer ilula, kulula ukuyisebenzisa. Ukuba umswakama ongama-40-60% (kwizinto ezikhethekileyo, ukuya kuthi ga kwi-90%) wolwelo ungomiswa ube yimveliso yomgubo, emva kokuba womile ngaphandle kokutyumza nokuhluzwa ukunciphisa iinkqubo zemveliso, ukuphucula ubunyulu bemveliso. Ukuze ubungakanani, ubuninzi bobuninzi, ukufuma, ngaphakathi koluhlu oluthile lunokulungiswa ngokutshintsha iimeko zokusebenza, ulawulo kunye nolawulo kulula kakhulu.

Ipharamitha yoBugcisa

| Imodeli/Into | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 2000 | 3000 | 4500 | 6500 | ||

| ubushushu bomoya wokungena (°C) | 140-350 Ulawulo Oluzenzekelayo | ||||||||||||||

| ubushushu bomoya obuphumayo (°C) | 80-90 | ||||||||||||||

| Indlela yokuthomalalisa | I-atomizer ye-centrifugal ekhawulezayo ephezulu (ukudluliselwa koomatshini) | ||||||||||||||

| Ukufuma kwamanzi umda ophezulu (kg/h) | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 2000 | 3000 | 4500 | 6500 | ||

| Umda ophezulu wesantya (rpm) | 25000 | 22000 | 21500 | 18000 | 16000 | 12000-13000 | 11000-12000 | ||||||||

| Ububanzi bediski yokutshiza (mm) | 60 | 120 | 150 | 180-210 | Ngokweemfuno zenkqubo yobugcisa | ||||||||||

| umthombo wobushushu | Umbane | umphunga + umbane | Umphunga + umbane, ioyile yepetroli, igesi, isitovu esishushu | ||||||||||||

| Amandla okufudumeza ngombane umda ophezulu (kw) | 12 | 31.5 | 60 | 81 | 99 | Ukusebenzisa omnye umthombo wobushushu | |||||||||

| Ubukhulu (L×W×H) (m) | 1.6×1.1×1.75 | 4×2.7×4.5 | 4.5×2.8×5.5 | 5.2×3.5×6.7 | 7×5.5×7.2 | 7.5×6×8 | 12.5×8×10 | 13.5×12×11 | 14.5×14×15 | Imiselwe ngokwemeko yokwenyani | |||||

| Imveliso yomgubo izinga lokubuyisela kwimeko yesiqhelo | Malunga ne-95% | ||||||||||||||

Imfutshane

I-Spray Dryer, i-Spray dryer tower yinkqubo yokwenza ulwelo kwaye ishishini lenkqubo yokomisa lelona lisetyenziswa kakhulu. Eyona ifanelekileyo ekuveliseni umgubo ovela kwi-suspension emulsions, izisombululo, i-emulsions kunye ne-paste liquid, imveliso eqinileyo ye-granular. Ke ngoko, xa usasazo lobungakanani be-particle yemveliso egqityiweyo, umxholo womswakama oseleyo, uxinano olukhulu kunye nokwakheka kwe-particle kuhambelana nomgangatho ochanekileyo, i-Spray Dryer ifanelekile kwinkqubo yokomisa.

Itshati yoMqukuqelo

Isicelo

Iimveliso zeekhemikhali: I-PAC, iidayi ezisasazwayo, iidayi ezisabelayo, ii-catalysts ze-organic, i-silica, umgubo wokuwasha, i-zinc sulfate, i-silica, i-sodium silicate, i-potassium fluoride, i-calcium carbonate, i-potassium sulfate, ii-catalysts ezingaphiliyo, zonke iintlobo zenkunkuma.

Ukutya: ii-amino acids, iivithamini, amaqanda, umgubo, isidlo samathambo, iziqholo, iiproteni, umgubo wobisi, isidlo segazi, umgubo wesoya, ikofu, iti, iglucose, i-potassium sorbate, i-pectin, iincasa kunye neziqholo, ijusi yemifuno, igwele, istatshi, njl.

Iiseramikhi: I-Alumina, i-zirconia, i-magnesia, i-titania, i-titanium, i-magnesium, i-kaolin, udongwe, ii-ferrites ezahlukeneyo kunye nee-oxide zesinyithi.

Umxube weGranulator weQuanpin Dryer

I-YANCHENG QUANPIN MACHINERY CO., LTD.

Umenzi ochwephesha ogxile kuphando, uphuhliso kunye nokuveliswa kwezixhobo zokomisa, izixhobo ze-granulator, izixhobo zokuxuba, izixhobo ze-crusher okanye ze-sefa.

Okwangoku, iimveliso zethu eziphambili ziquka umthamo weentlobo ezahlukeneyo zokomisa, ukugaya, ukutyumza, ukuxuba, ukugxila kunye nokukhupha izixhobo ezifikelela kwiiseti ezingaphezu kwe-1,000. Ngamava atyebileyo kunye nomgangatho ongqongqo.

https://www.quanpinmachine.com/

https://quanpindrying.en.alibaba.com/

Ifowuni ephathwayo:+86 19850785582

I-WhatApp:+8615921493205